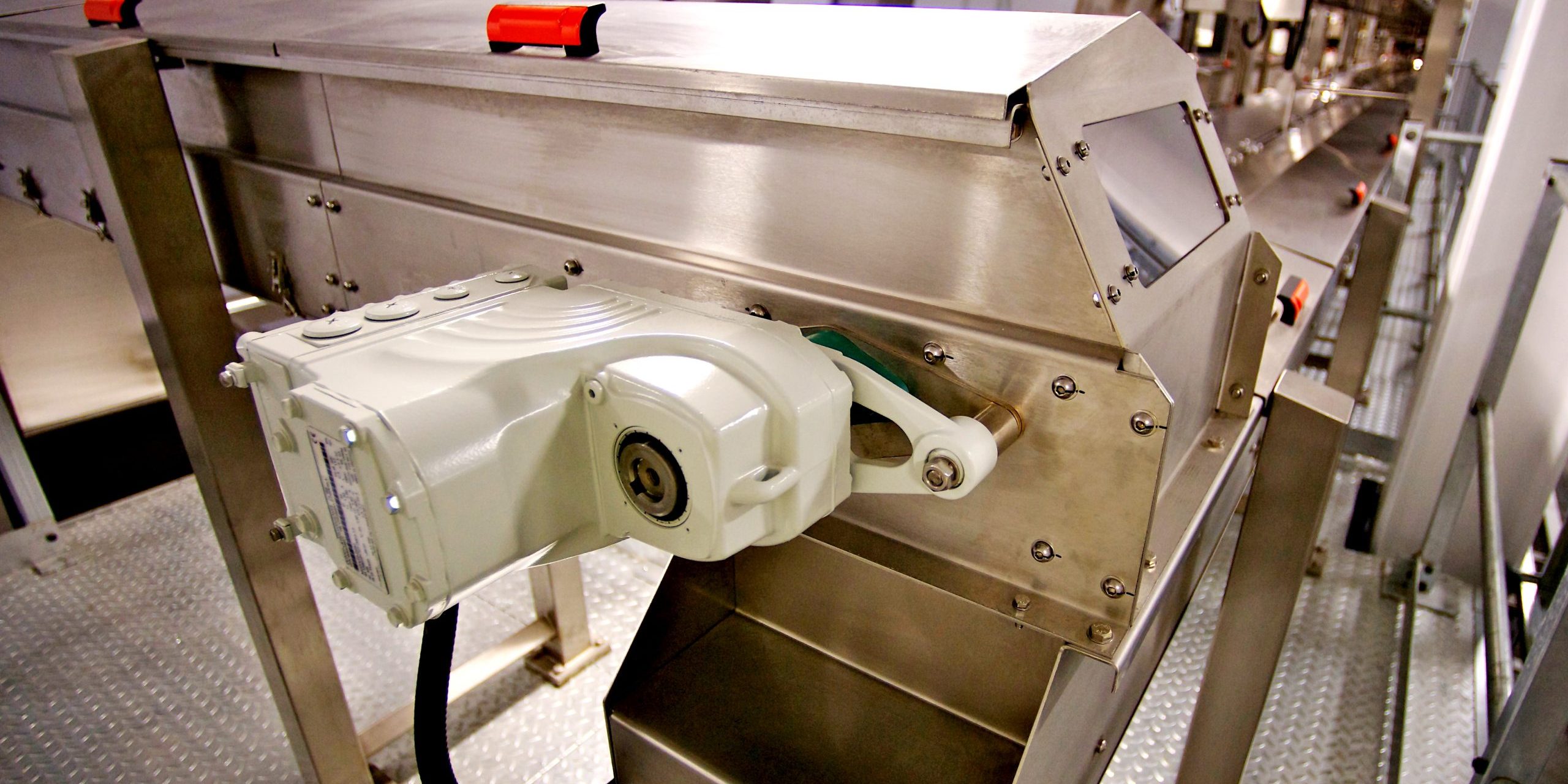

Conveyor systems play a central role in the warehouse of any manufacturing industry, therefore conveyor service and maintenance is crucial. Here are some things to keep in mind to keep your conveyor system reliable so you can continue delivering a high-quality service.

Spares

Keeping spares on site is fundamental to reduce the risk of losing valuable time if your operation grinds to a halt due to a failed part. Asmech Systems Ltd. can help with advice on what spares are best to have to hand so you don’t lose days of production time. We also have a wide variety of spares to order from to maintain that list.

Cleaning

Cleaning is another fundamental aspect of conveyor maintenance. The area around the conveyor needs to be kept nice and tidy as loose debris can result in a jam in the belt or drive causing unnecessary wear and tear. Having a regular cleaning routine in place will reduce the risk of this happening but for safety reasons make sure the conveyor is powered down to be cleaned properly.

Regular inspections

Another routine to have in place is regular inspections of your conveyor. At least once a month make sure to have visual and audio checks. Look for anything missing or loose and listen for anything that doesn’t sound right.

Conveyor misuse

Maintaining your conveyor means treating it properly, make sure anyone who is using it has been fully trained on how to safely use the equipment. Take extra care to not overload the conveyor, any unexpected weight can lead to increased wear and tear on essential parts such as belts and chains.

Seek expert advice

Whether it’s installing a spare part or confirming something found from an inspection, having a qualified maintenance technician is important to maintain a healthy conveyor system. We have an expert knowledgeable team who as part of our after sales service will come out to service and maintain your system. Please get in touch and chat about your needs with our team today.