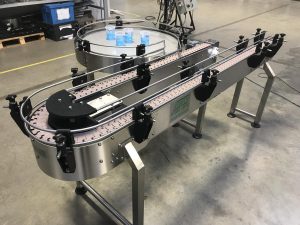

Asmech Systems Ltd. offer a range of bespoke rotary table systems, made to customer requirements. They can be used in a variety of industries including engineering, manufacturing (metal industry), and food industries, even oil rigs.

Rotary table systems convey and position components during the manufacturing process. The indexing unit rotates items to a specific position,. These can be either fixed or variable and securely revolves the product around a table. These indexers are often used to place objects at exact points around a workspace so that they can be worked on, like a circular assembly line.

Rotary table systems for the food industry

For the food industry they are hygienically constructed, with a choice of a stainless-steel grade 304, complete with an SEW Eurodrive motor and isolator as standard. Fitted with side guides and a variable speed control, the product can securely revolve around the table. It can be added to your existing production line or use as a standalone machine.

Rotary tables used in a conveyor context are sometimes called “accumulation stations” or even “food production tables”. These solutions are renowned for the way they deliver additional packing time.

Reliability

Asmech Systems Ltd make some of the most efficient and reliable rotary table systems in the UK, manufactured from high grade materials to ensure longevity of your system. We have been supplying world class businesses for over 20 years. Bespoke systems to your requirements can be tailored to different sizes, heights and various settings, along with a numerous amount of customisation options as well as different rotational speeds, all designed to fit your business in the best possible way. Designed and manufactured in-house at Asmech Systems Ltd, requiring very little maintenance and guaranteed to keep production moving.

Asmech Systems Ltd make some of the most efficient and reliable rotary table systems in the UK, manufactured from high grade materials to ensure longevity of your system. We have been supplying world class businesses for over 20 years. Bespoke systems to your requirements can be tailored to different sizes, heights and various settings, along with a numerous amount of customisation options as well as different rotational speeds, all designed to fit your business in the best possible way. Designed and manufactured in-house at Asmech Systems Ltd, requiring very little maintenance and guaranteed to keep production moving.

Usage

Rotary table systems are usually situated at the beginning or end of a production line, the product is fed on by a conveyor, and the product is singulated or accumulated on the table, allowing the operators to pack the product or pick and place on to pallets or totes.

One of the main purposes of rotary tables in work environments is to give operators extra time to pack products whilst the efficiency of the entire production line is enhanced meaning heightened production for your business. You can find out more information here.

Do you have a requirement in mind? If so, we would love to have a chat to you.