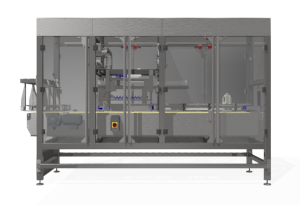

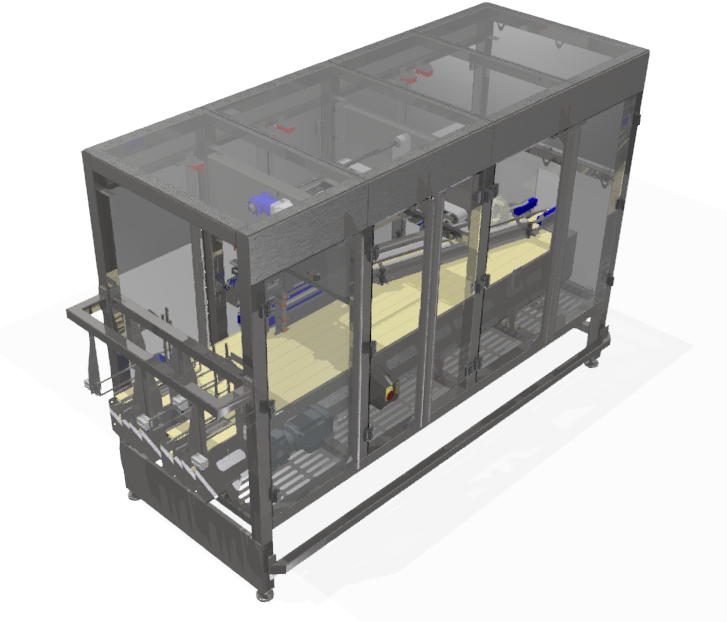

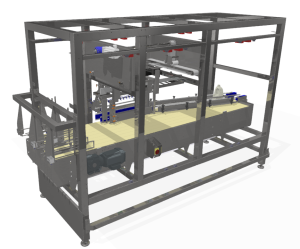

Dynamic Diverter: Optimising Bottled Product Handling for Dairy and Beyond

Streamline the flow of bottled products on your production line with the Dynamic Diverter, an advanced solution tailored for industries handling a variety of bottled goods. Whether you’re in the dairy, beverage, pharmaceutical, or consumer goods sector, the Dynamic Diverter ensures seamless product rerouting, minimising downtime and enhancing efficiency.

What is a Dynamic Diverter?

The Dynamic Diverter is an automated device designed to reroute bottled products smoothly and accurately across your production or packaging lines. Unlike traditional systems that may require manual adjustments or pauses in production, the Dynamic Diverter operates continuously and automatically, preventing bottlenecks and increasing throughput.

Key Features

Automated Product Rerouting: The diverter automatically directs bottled products between different conveyor paths, eliminating manual intervention and ensuring smooth, uninterrupted flow.

Gentle Handling for Fragile Bottles: Designed to handle a wide range of bottle types – including fragile dairy bottles – the diverter moves products with care, reducing the risk of breakage or product damage.

Versatile Configurations: Whether you’re directing bottles to multiple filling stations, packaging areas, or inspection zones, the Dynamic Diverter supports a variety of flow paths, providing maximum flexibility for production lines.

Precise Alignment: With advanced sensors and controls, the diverter ensures each bottle is accurately aligned and rerouted to its designated destination, reducing errors and misalignment.

High-Speed Performance: Capable of operating at high speeds, the Dynamic Diverter keeps up with fast-paced production environments, making it ideal for high-volume bottling operations.