What does palletising mean?

It means placing or stacking items onto a pallet made out of wood, plastic, or metal. Billions of pallets are used every day as it is a vital component for logistics to avoid damage or loss of products during transportation.

Traditionally palletising is performed manually with workers taking packaged items from a production line and stacking them onto pallets.

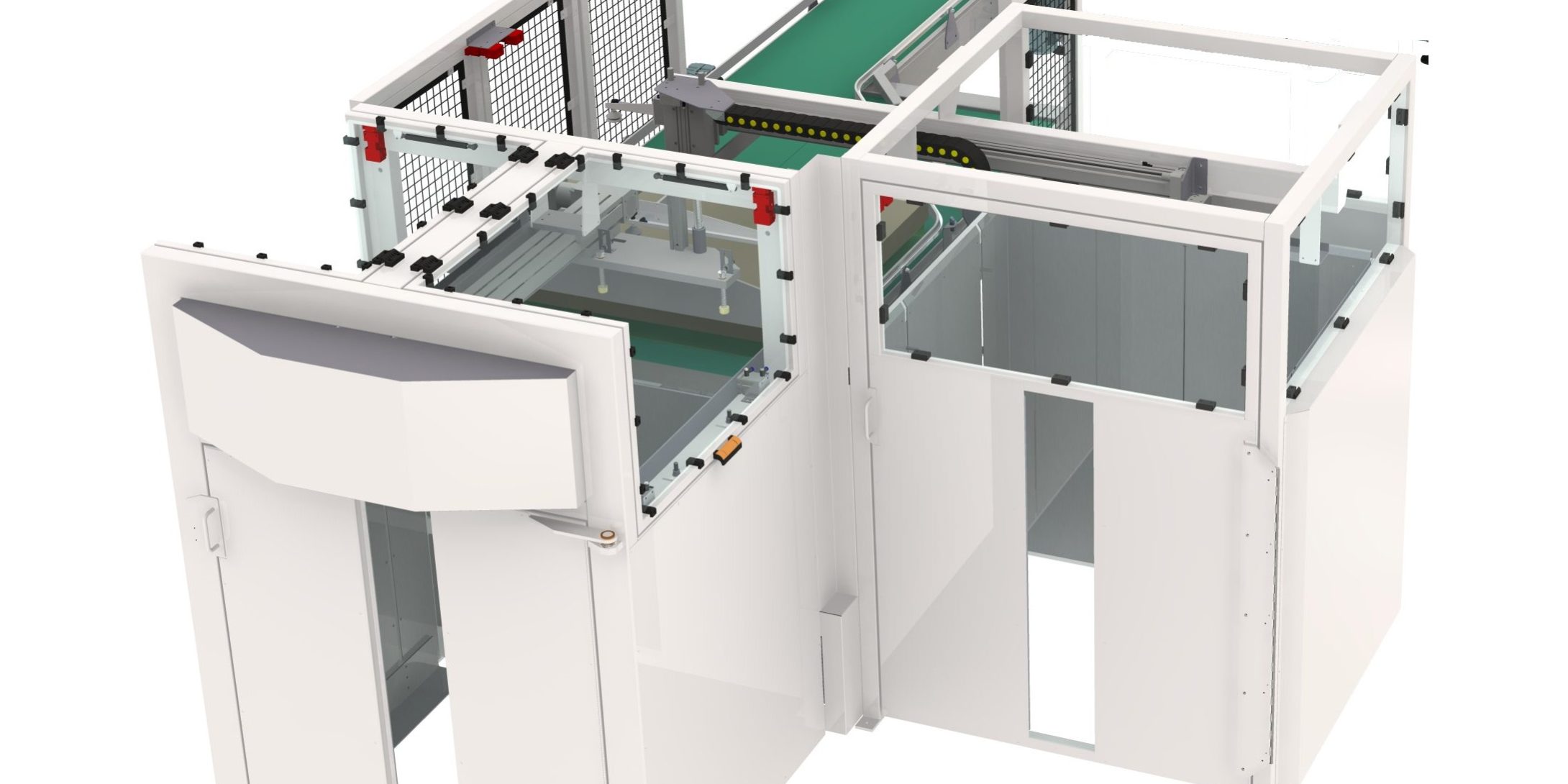

However, around 40 years ago automated palletisers were introduced and are a common popular way of achieving palletising in most warehouses today. They are more consistent than manual workers and have reduced the number of injuries that occur carrying out this task.

What is depalletising?

Depalletising is more complex than palletising, as it means systematically moving individual items such as boxes, bags and other packages from a loaded pallet into the warehouse. It is usually the first stage in the process of manufacturing where raw materials loaded on a pallet have arrived. This is also traditionally achieved by manual workers but even though it is more complex, automated depalletisers can perform this task.

Similarities between palletising and depalletising

They are quite similar tasks with both involving the movement of items from one place to another, meaning they can sometimes be performed by the same robot. They are dull and repetitive jobs that workers do not like to perform manually. When palletising operators perform more than one role they can often be a bottleneck to production.

Differences between palletising and depalletising

The main difference is the location of items, operators have more control when palletising as the robot will pick up from the conveyor belt and place items in a precise location on the pallet. With depalletising, the robots are picking items up from a pallet that has been loaded by someone else or the items may have moved in transit, meaning the depalletiser needs to be able to account for unexpected positions.

It is done at different times in the production process with depalletising at the start, unpacking and sorting products while palletising comes later in the process with items packed and sealed ready to be moved to the pallet.

Palletiser? Depalletiser? Both?

If you are looking to automate the palletising in your warehouse some things to consider are:

Are our bottlenecks mostly at the beginning or end of the workflow?

Where does the robot need to be placed?

Can the tasks be performed by the same robot or do we need both?

What is the quantity of product for the task?

For more information on the best solution for your warehouse palletising needs please contact our expert team on 01623 424442 or sales@asmechsystems.co.ukBottom of Form