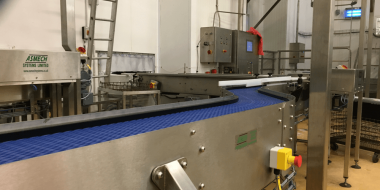

Modular conveyors are a flat belt conveyor often referred to as Radius belts and are made up of individual plastic or steel modules usually linked together using joint rods.

Modular belt conveyors offer a number of advantages including the curved sections of belts which are available. The modular belt is robust and can tolerate high and low-temperature products, perfect for the food and pharmaceutical industries as well as lots of other industries.

Modular belt conveyors are versatile and durable meaning the enhanced efficiency of assembly or picking line in your factory. Individual slats can easily be replaced meaning maintaining your system is a straightforward process. The characteristics of the belt itself mean products can be conveyed on inclined, horizontal and helical paths.

Food industry belt materials have to be FDA approved to ensure that no contamination is transferred while food stuff is being processed and manufactured.

As with any conveyor belt, the environment and requirements from the belt itself will determine the material used. Plastics used in the manufacture of modular belts are usually Polyethylene, and Polyproplene for food production, while, polycetal is not usually recommended. It’s a good all-rounder plastic and typically strong, however it’s sensitive to impact, and can be damaged easier than other plastic module belts. Nylon is a soft material, with high impact strength with excellent chemical resistance. Nylons are also FDA approved and is versatile enough to use in applications of both cold and arm areas, as it performs well in different temperatures.

We offer bespoke manufacture of belt conveyors and it is important to get the right information for the application, we can work with you for that perfect solution.

Polyproplene

Used for belts that may be used in extremely hot temperatures of up to 100 degrees Celsius. It is hard and creates a strong pulling force, and can be used for conveying heavier loads as it drives the belt forward. Polyproplene has strong resistance to chemicals, making it easy to maintain and clean.

Polyethylene

Usually for colder temperature, it has good strength for pulling, is strong and resistant to impact and can be used in areas of up to -75 degrees Celsius. Polyethylene has a much longer life span than alternatives.

Generally designed with hygiene in mind Asmech Systems modular conveyors are typically made from Stainless Steel Grade 304 (mild steel powder coated available if required) and is available in a range of lengths that can be made to measure using splice joints. We supply all types of material and widths for conveying a wide variety of product from food preparation to bottle and pack distribution, with or without flights.

Contact us for a chat, we are happy to help. 01623 424 442 or drop us an email and we will call you straight back. sales@asmechsystems.co.uk