‘’Bottlenecks” – a word that sends shivers down the spine of anyone in production and manufacturing. It’s the silent productivity killer that every operator and manager is trying to eliminate. They’re constantly on the hunt for solutions that not only get the job done but do so efficiently and for the long haul.

What if we told you that the hunt is over?

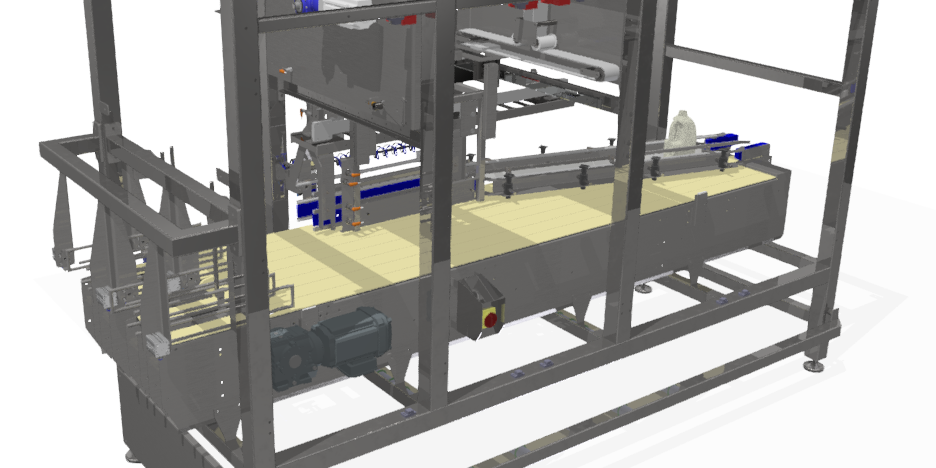

At Asmech Systems Ltd, we’ve designed the Dynamic Diverter to do just that – automatically rerouting bottled products with precision and speed, ensuring your production line operates seamlessly from start to finish.

The Problem: Frequent Stoppages Slowing Your Production

In bottling operations, the production line must handle fragile products like milk bottles, yogurt containers, carbonated drinks, and other beverages. But what happens when manual rerouting or misaligned products lead to delays?

- Filling stations get backed up, waiting for the line ahead to clear.

- Capping and labelling stations lose efficiency as products fail to arrive at the right time.

- Manual interventions increase the risk of damage, waste, and costly stoppages.

This all adds up to higher operational costs, reduced efficiency, and a slower overall workflow.

The Solution: Automated Product Rerouting with the Dynamic Diverter!

The Dynamic Diverter changes the game by automating the entire rerouting process, keeping your production line moving without a hitch.

- No more manual intervention: The diverter automatically directs bottled products between conveyor paths, ensuring the right products reach the right stations – whether it’s for filling, capping, or labelling.

- Precise alignment: Advanced sensors ensure every bottle is aligned perfectly, reducing the risk of mis-steps that slow down the process.

- Continuous flow: No bottlenecks, no pauses – just a smooth, uninterrupted production line from start to finish.

Experience the Benefits Firsthand

When you invest in the Dynamic Diverter, you’re investing in:

- Reduced Downtime: Automated rerouting minimises line stoppages, keeping production flowing smoothly.

- Increased Efficiency: With less manual intervention, your team can focus on other high-value tasks, while the diverter ensures products are rerouted without delays.

- Enhanced Flexibility: Whether you’re bottling milk, juices, or other bottled products, the diverter adapts to different product types, shapes, and sizes with ease.

Don’t let frequent stoppages impact on your production line. With Asmech’s Dynamic Diverter, your bottling process becomes more efficient, more reliable, and more productive.

Bring It to Your Shop Floor

Curious to see how the Dynamic Diverter could transform your production line? Our team would love to show you! Let’s bring this innovative solution directly to your shop floor.

Get in touch with one of our friendly experts to explore how the Dynamic Diverter can boost efficiency, cut downtime, and make your bottling process smoother than ever. We’re here to help every step of the way!

Call us (01623) 424 442 or send an e-mail to sales@asmechsystems.co.uk