Blow Molding Sector Innovation

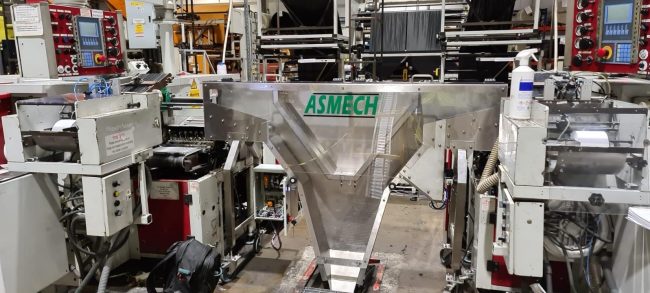

Challenge Our client, a well-established manufacturer in the blow molding industry, required a fully integrated conveyor system to optimise the flow of plastic preforms and blown bottles within their production facility. The project presented several key challenges: Limited space between the blow molding machine and the filler, restricting conventional accumulation options. Slow filler speeds, which…