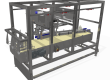

Asmech Systems Ltd are renowned for working with our clients to create bespoke engineering solutions tailored to the unique needs of our clients, including system upgrades, such as a recent project to deliver a comprehensive system upgrade, including the design, manufacture, and installation of side-gripping loop inverters and integration of the associated conveyor lines.

This recent project required an innovative solution to enhance their production process, with the ultimate goal to efficiently invert bottles to coat the underside of caps with juice while ensuring seamless integration into their existing production line.

Side-gripping loop inverters and integrated conveyor lines play a crucial role in drinks manufacturing, offering several key advantages:

Gentle Handling:

- Side-gripping mechanisms minimise contact with the bottle’s surface, reducing the risk of damage, label scuffing, or contamination.

- Loop inverters provide a smooth and controlled inversion process, essential for delicate or carbonated beverages.

Increased Efficiency:

- Automated inversion eliminates the need for manual handling, significantly improving production speed and throughput.

- Integrated conveyor systems ensure a continuous and uninterrupted flow of bottles throughout the production line, maximising productivity.

Improved Product Quality:

- Consistent and controlled inversion minimises the risk of product spillage or leakage, maintaining product integrity.

- Reduced handling minimises the risk of contamination, ensuring product safety and quality.

Enhanced Flexibility:

- Modular conveyor systems can be easily adapted to accommodate various bottle sizes and shapes, providing flexibility in production lines.

- Loop inverters can be customised to suit specific product requirements and production needs.

Space Optimisation:

- Compact and efficient designs of inverters and conveyor systems help to optimise production floor space.

By incorporating side-gripping loop inverters and well-integrated conveyor lines, drinks manufacturers can achieve significant improvements in production efficiency, product quality, and overall operational performance.

You can read more, on this particular project and full case study here:

https://www.asmechsystems.co.uk/case-study/soft-drinks-bottle-inverter

Contact us today to speak to our knowledgeable team about our bespoke systems, products and services on 01623 424 442 or at sales@asmechsystems.co.uk