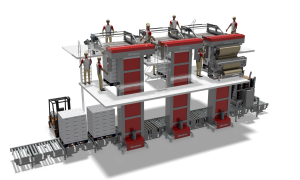

Qimarox Crossrunner is a space saving solution for in-line placing of multiple palletisers. Thanks to the unique design, a single roller conveyor is sufficient to feed pallets in and out for multiple palletisers operating in line. The products are supplied by means of a feed belt that is placed on left or right side of the formation system. Each individual product is placed on an exact location until a full row of product is formed. Each formed row is placed onto an buffer where it remains until a layer is complete. By depositing an entire layer at a time, the Highrunner HR7 needs to make fewer movements. This saves time, increasing the capacity when compared to other palletising systems.

Pallets pass along the bottom of the unit

Because the pattern-formation conveyor and pallet lift are placed higher, both empty and full pallets can pass underneath at floor level via the central roller conveyor.

In other words, in an arrangement with for example, three Crossrunners next to each other, a full pallet from the first machine can be carried away under the second machine while this second machine simply continues palletising. Conversely, it is possible to transport an empty pallet to the second machine under the first machine via the roller conveyor without hindering the first machine at all.