These bagger and debagger systems sort bottles into sanitised and heat-sealed plastic packages, making them easy to handle and store. They vary in design, height, and container designs and configurations. These conveyor systems are generally a cost-effective way to move containers throughout your workplace, while controlling accumulation and surge.

Bagger

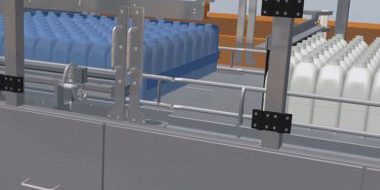

The Asmech Systems bagger is used to automatically bag square, rectangular, and round containers usually from blow-moulders for storage or export. This machine has the ability to bag different containers from different blow-moulders simultaneously while operating in either full automatic or semi-automatic modes.

Each bottle conveyor entry can be fully customised to suit unique workplace layouts, with bottle positioning devices, is easy to set up and operate, offering low maintenance. This machine will increase efficiency and productivity of the product lines.

The semi-automatic bagger pushes the bottles into the bags, once the operator confirms the bags are placed in the bagging clamps and that the machine is ready, a live feed conveyor automatically transfers the containers into the bagger, so that they can be collated. The bags are then sealed ready for storage.

The capacity of the conveyor, based on a 4 Pint (2 Litre) Milk Bottle, is 100 bottles per minute. We do however also offer a higher speed option that will bag 200 bottles per minute. Get in touch if this option is more suitable that a one lane bottle feed for your product.

Debagger

Made of a simple design, this high quality machine offers long lasting reliability. Able take bags of product on pallets eight layers high, taking one layer and removing the bag. The system will then single the batch of bottles onto an Asmech Systems Ltd. standard slat conveyor ready to be filled.

The De-Bagger system uses a series of electrical motors, belts and pneumatic cylinders to handle the product. It has a function that deposit the pallets into a small storage area to be re-used. It is suitable for any hygienic environment and is capable of various speeds.

The Automatic De-Bagger is versatile and is designed to meet customer requirements and specifications. All our systems offer continuous flat belt pack accumulations, the machine does not need to be stopped when a new pack is introduced.